Suction nozzle packaging bags are mainly divided into ordinary suction nozzle bags and high-temperature resistant suction nozzle bags. Ordinary suction nozzle bags mainly consider safety, firmness and reusability, such as liquid packaging bags and detergent packaging bags, while high-temperature cooking bags should consider food safety. How to ensure that the material solvent ink will not be dissolved in the process of high-temperature cooking. It can also ensure that the nutritional components of the product are not lost and taste change.

Ordinary suction nozzle packing bag

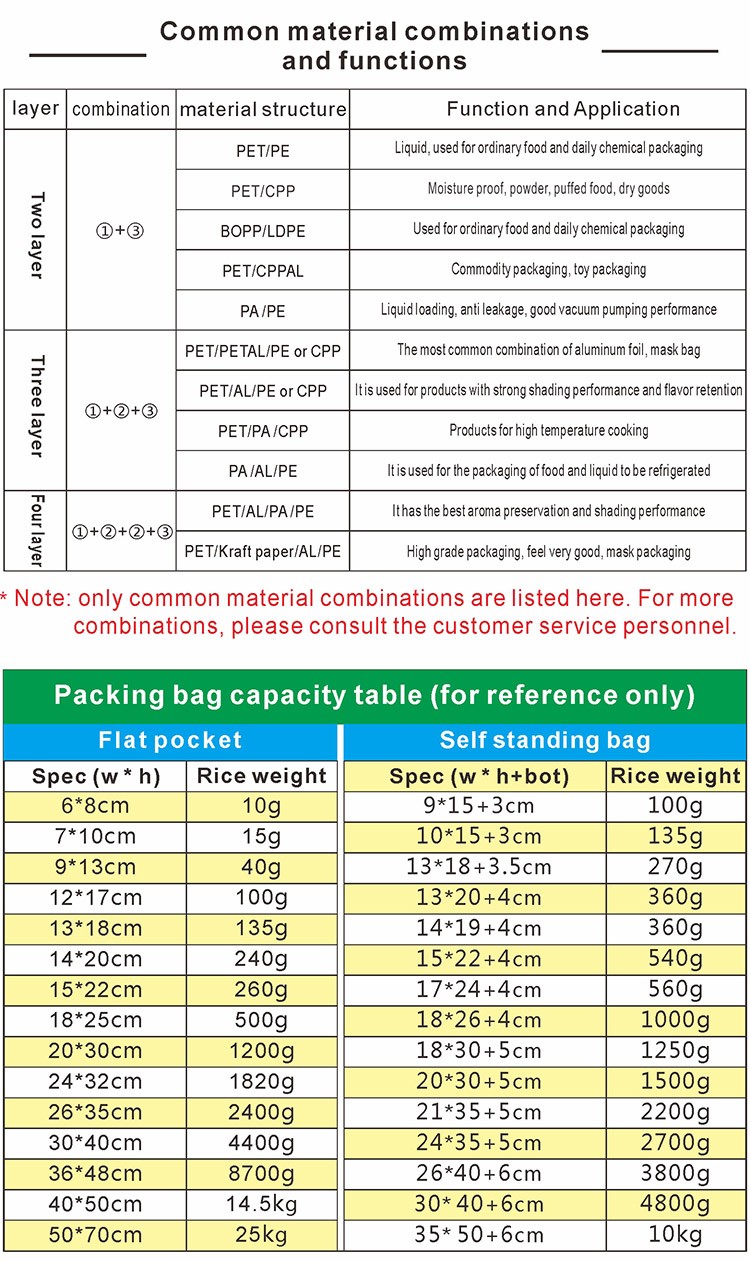

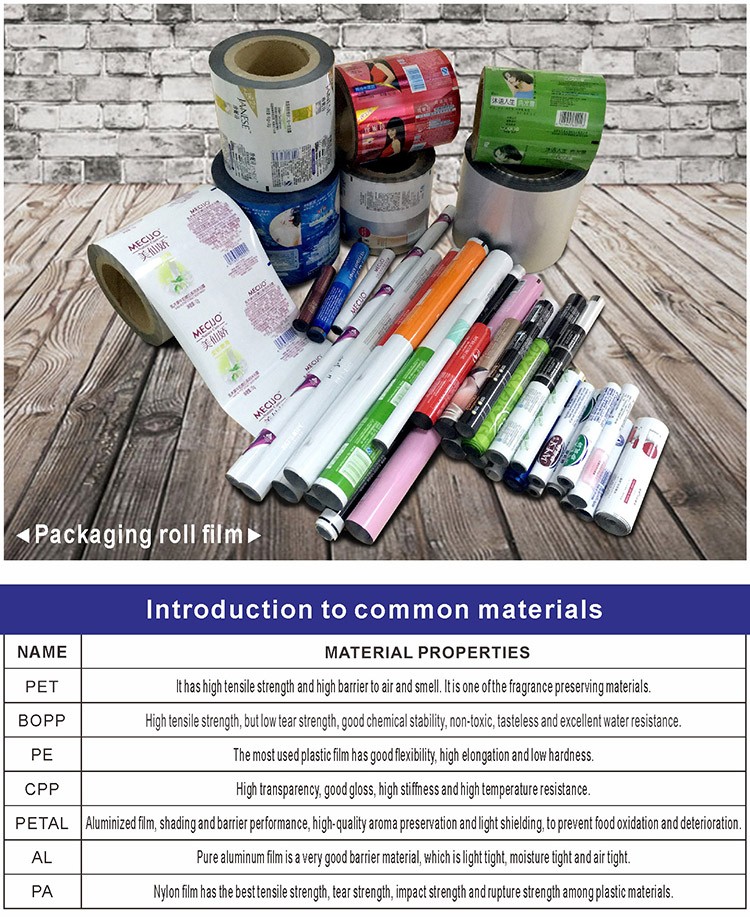

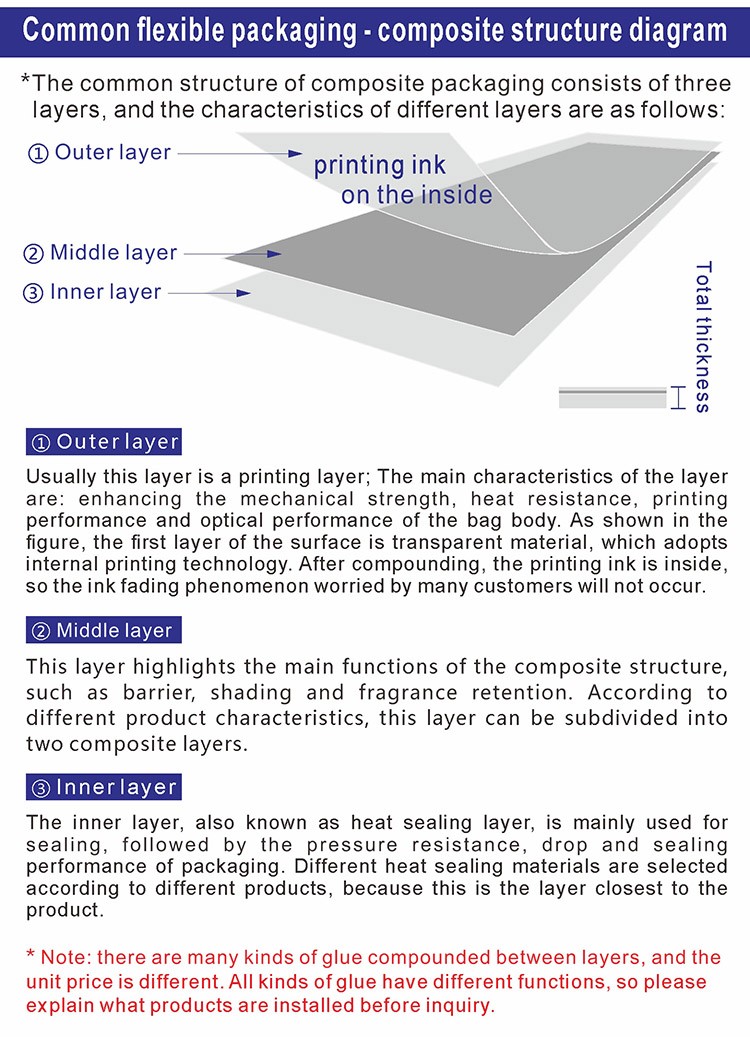

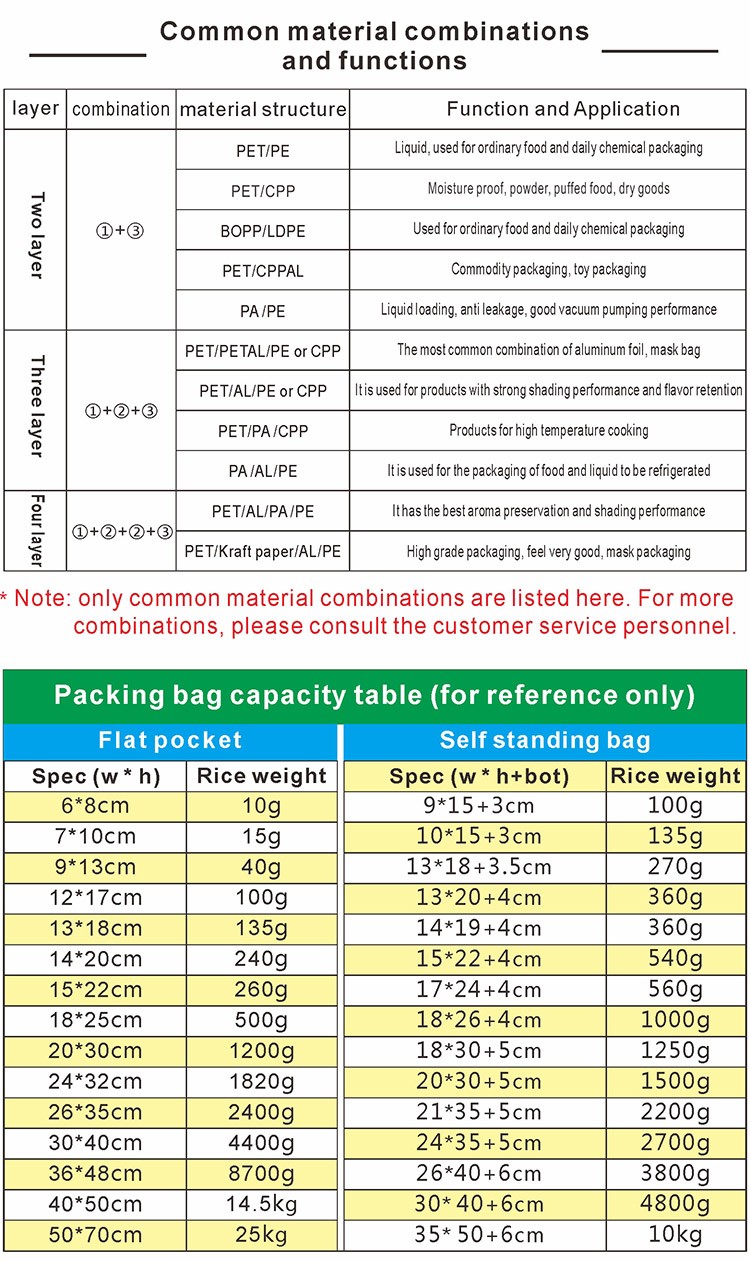

1. PET / PE, PA / PET / PE, PET / PE / aluminized / yopp, PET / PE / yopp, etc. are recommended for common materials

2. The material solvent of ordinary nozzle packaging bag has no particularly high requirements, as long as it can ensure that the material has stable chemical properties, non-toxic and tasteless, and will not decompose at room temperature. It has certain acid and alkali resistance and explosion resistance!

3. Control the friction coefficient of the film. When the automatic filling machine is filling, the outer surface of the packaging bag film shall maintain good smoothness, so as to increase the fluidity of the liquid and fill smoothly during the high-speed operation of the automatic packaging machine.

4. When matching materials, attention should be paid to the properties of the materials. If the materials are too soft, the tension of the suction nozzle packaging bag will be very poor, there will be no three-dimensional feeling, and it is easy to break under the tension of the high-speed automatic filling machine.

High temperature cooking suction nozzle packaging bag

1. Three layer materials are recommended for common materials: PET / pure aluminum / rcpp, PPET / PA / rcpp. Four layer material: PET / pure aluminum / PA / rcpp

2. Due to the special purpose, the material performance will be taken as the key consideration standard. Such as acid resistance, alkalinity, impact resistance, freezing resistance, barrier, etc.

3. The above materials have extremely stable chemical properties at high temperature. It is suggested to select a large-scale and experienced packaging bag manufacturer for the problem of whether the composite solvent will decompose.

4. Pay attention to the sterilization methods. There are two methods of high-temperature sterilization, high-pressure sterilization and low-temperature atmospheric sterilization. The advantage of low temperature and normal pressure sterilization is that the stability of heating is relatively low, so the cellulose and protein of food are not destroyed, and the taste is better and unchanged. And all kinds of nutrients are well preserved. The disadvantage is that low temperature only kills pathogenic bacteria, and there will be a large number of spoilage bacteria in food, so the shelf life of food will be shorter than that of high temperature sterilization, and it is easy to cause product loss during transportation. High temperature and high pressure sterilization just solves this problem. In the environment of high temperature and high pressure, most bacteria and spoilage bacteria will be killed, so the shelf life of the product can be greatly extended. However, the problem is that the high heating temperature will destroy the cellulose and protein of food, resulting in the loss of some nutrients and the discount of taste.