Main applications of cup cover film: Soybean Milk Recipe cover film, yogurt cover film, probiotic cup cover film, jelly cup cover film, mung bean smoothie cover film, bottle cover sealing film, etc.

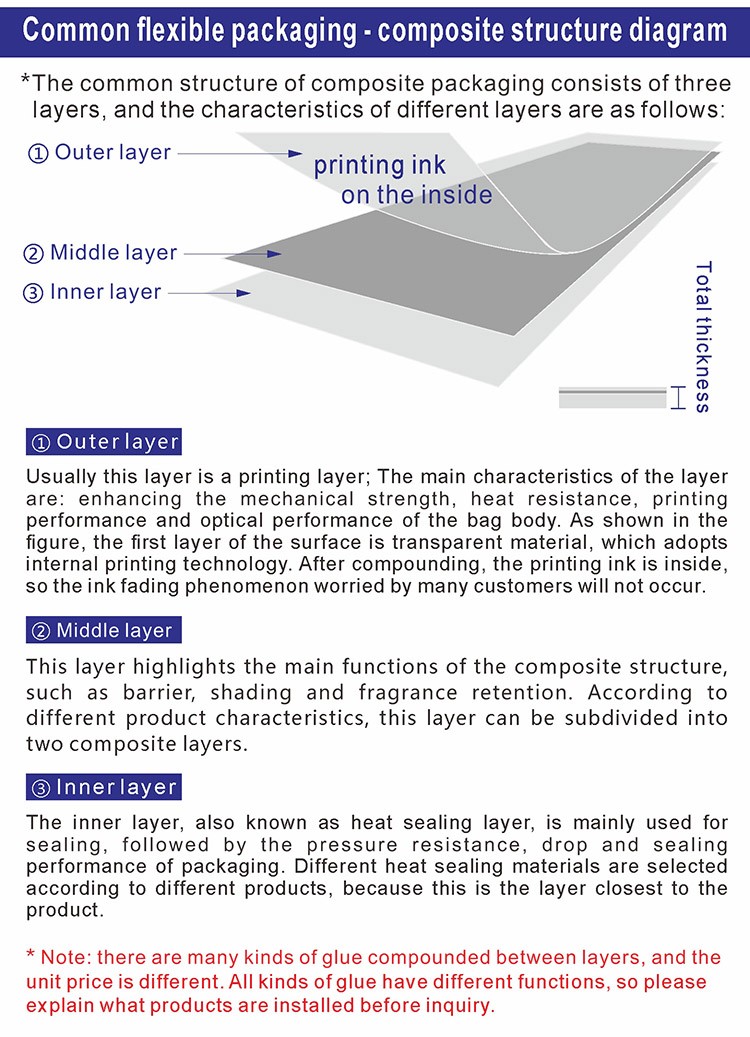

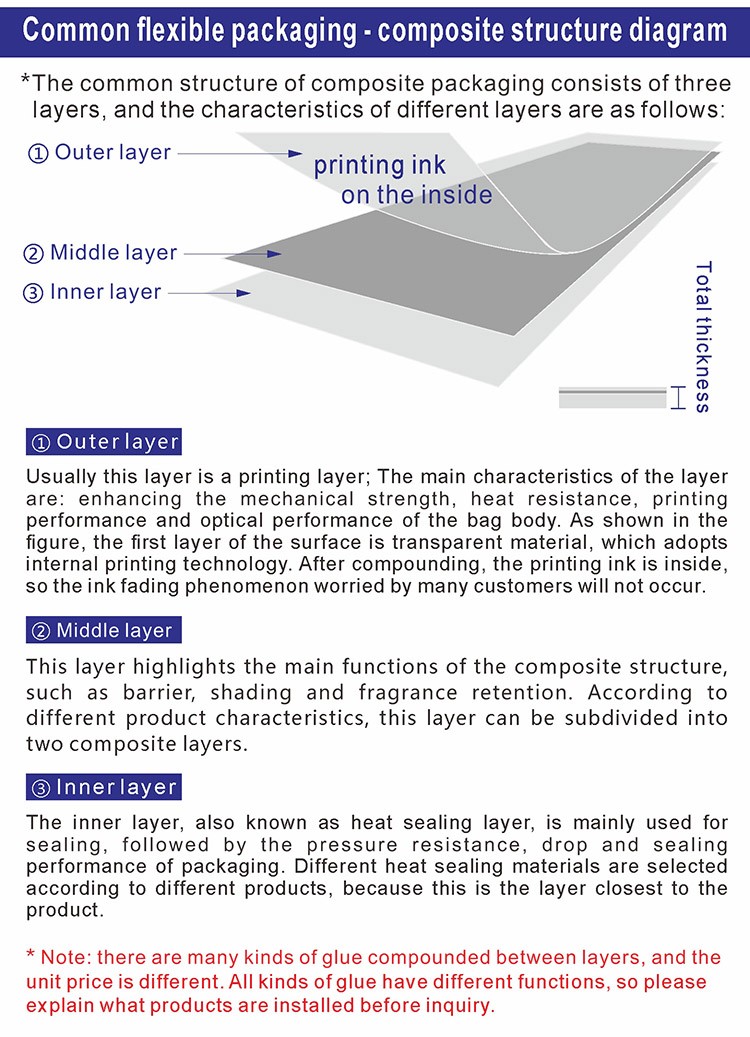

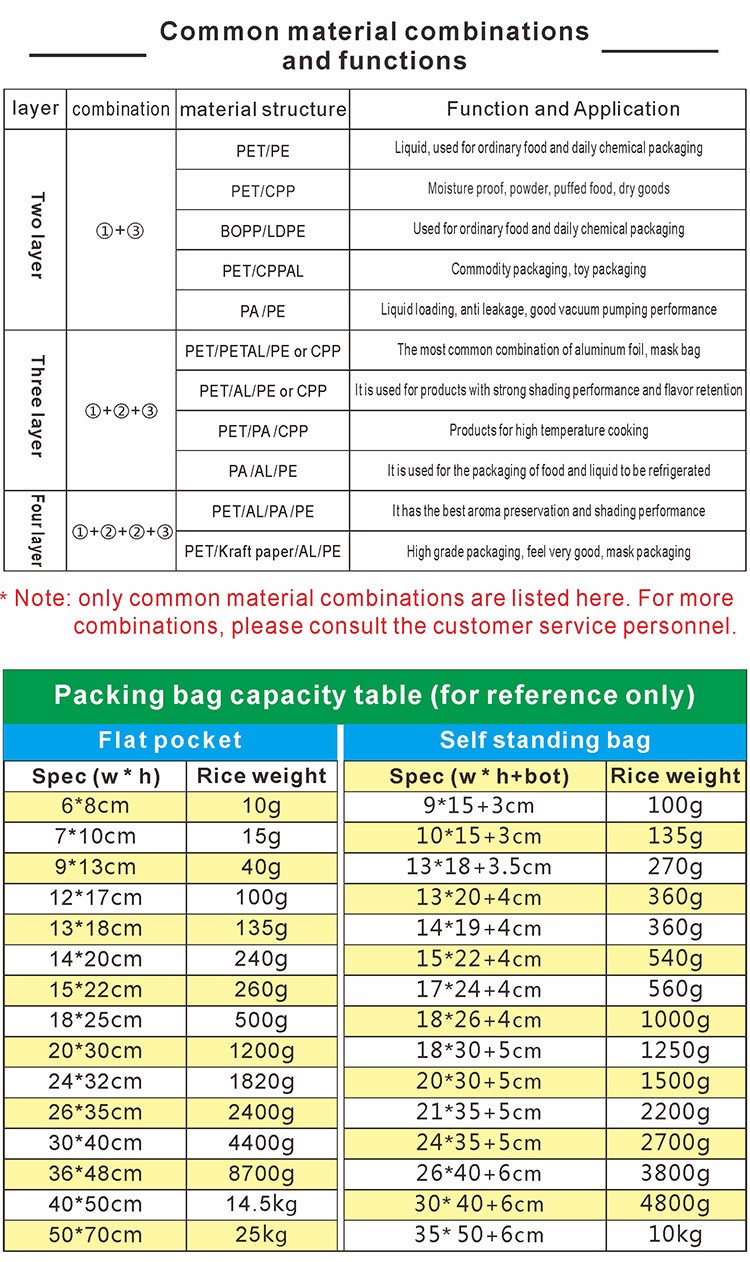

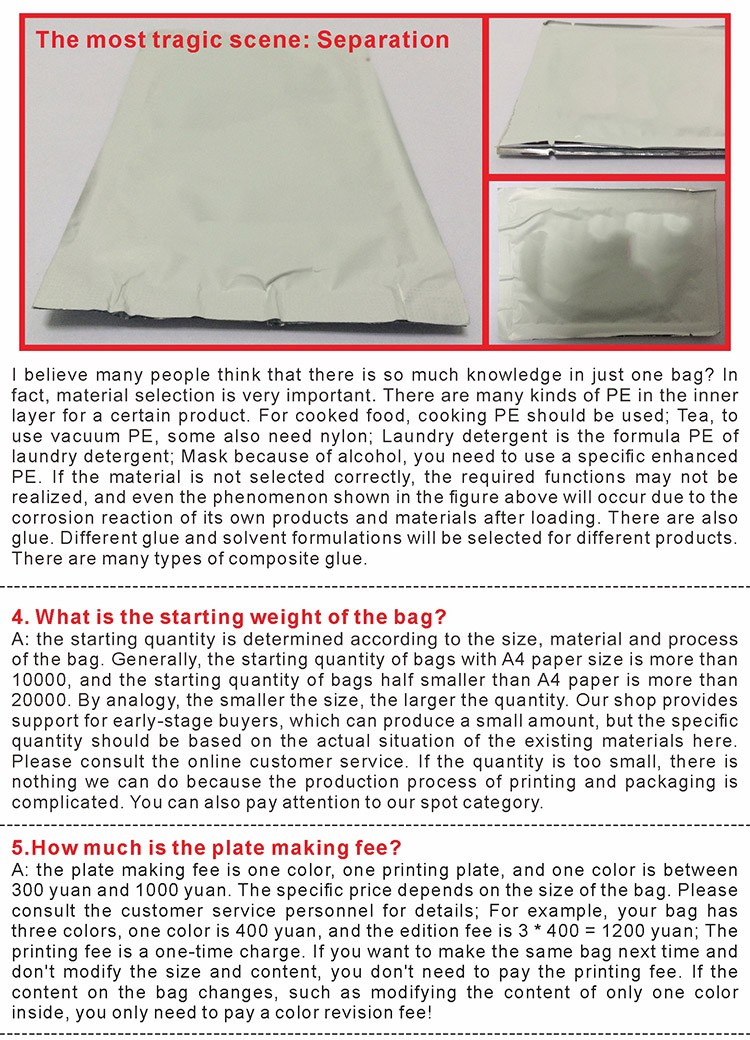

In fact, lamination in composite flexible packaging materials means lamination, which means that films of different properties or other flexible materials are bonded together, and then sealed to carry, protect and decorate the contents. The laminated structure of flexible packaging can be classified in many forms according to different combinations. However, conventional structures are usually distinguished by outer layer, middle layer, inner layer, adhesive layer, etc.

(1) Outer material

The outer layer material usually adopts the material with good mechanical strength, heat resistance, good printing performance and good optical performance. The most commonly used materials are polyester (PET), nylon (NY), stretched polypropylene (BOPP), paper and other materials. The requirements and functions of outer materials are shown in the table below:

Requirements and functions of outer materials

Interlayer materials are usually used to strengthen some characteristics of composite structures, such as barrier, shading, fragrance retention, strength and so on. The most commonly used are aluminum foil (AL), aluminized film (VMCPP, VMPET), polyester (PET), nylon (NY), polyvinylidene chloride coated film (kbopp, kpet, Kony), EVOH and other materials. The requirements and functions of intermediate layer materials are shown in the table below.

Requirements and functions of intermediate layer materials

(3) Inner material

The key function of the inner material is sealing. The inner structure is in direct contact with the contents, so it is required to be non-toxic, tasteless, water-resistant and oil-resistant. The commonly used materials are cast polypropylene (CPP), ethylene vinyl acetate copolymer (EVA), polyethylene (PE) and its modified materials. The requirements and functions of inner layer materials are shown in the table below:

Requirements and functions of inner layer materials

(4) Adhesive layer

The function of the adhesive layer is to bond two adjacent layers of materials together to form a composite structure. According to the characteristics of adjacent materials and composite technology, adhesive or adhesive resin can be used as the adhesive layer material. The bonding strength between adhesive laminates and bonded materials is an important index to evaluate the internal properties of composite packaging materials. Different packaging requirements have different requirements for this index.