The so-called glass water is also called wiper. It is a name for car windshield cleaning fluid. Glass water is mainly composed of water, alcohol, ethylene glycol, corrosion inhibitor and various surfactants. It has the functions of antifreeze, wetting, penetration, solubilization and decomposition of dirt. According to different antifreeze temperatures, glass water is generally divided into summer type, four seasons universal type and antifreeze type. According to different concentrations, glass water is concentrated type and non concentrated type. No matter which type of glass water, the production process is similar, but the difference is the production formula.

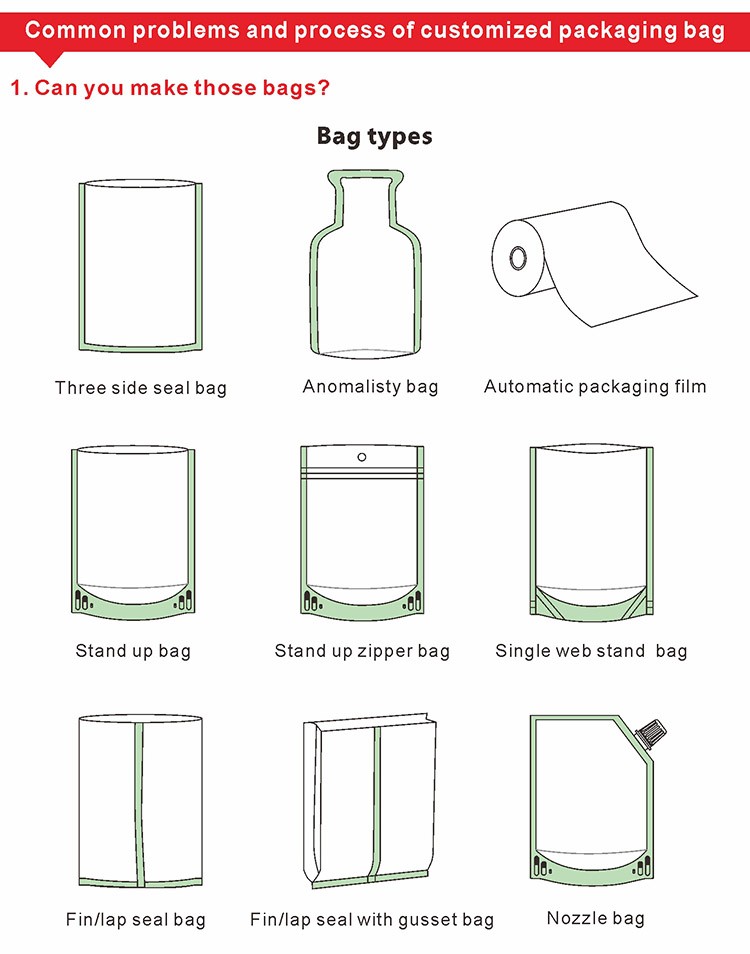

The glass water self-supporting suction nozzle bag is composed of a suction nozzle and a self-supporting bag. The self-supporting bag is composed of packaging materials, and the suction nozzle is a bottle mouth made of plastic.

Generally, it is used to package liquids, such as soybean milk, soy sauce, vinegar, fruit juice, beverage, laundry liquid, milk, etc. As the suction nozzle of the suction nozzle bag has various forms, there are long nozzles for jelly, fruit juice and beverage, as well as suction nozzles for washing products. With the continuous improvement, development and application of nozzle bags, most washing liquids and softeners in Japan and South Korea are packaged in nozzle bags, which are loved by foreign friends. This is the rhythm of the gradual transfer of plastic packaging bags to self-supporting suction nozzle bags. Northern winter is cold, Baijiu is loved by the northern people, and it's a little bit stronger and stronger. If people use the soft package with long mouth to make the package, it is convenient for people working in the field to sprinkle with body temperature or warm with hot water, which is convenient for drinking. Nowadays, the advertising industry is developing rapidly. If we make full use of the advantages of convenient printing and good printing quality of flexible packaging, we can print advertisements on the self-supporting suction nozzle bag, which is easy to carry, widely spread and has the benefit of killing two birds with one stone.

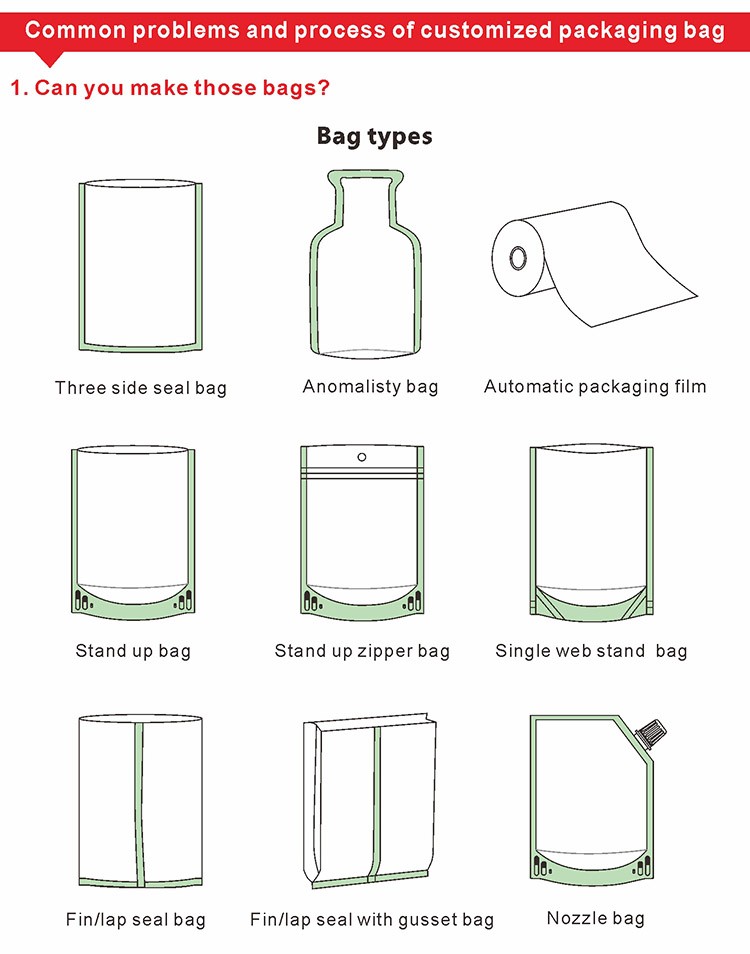

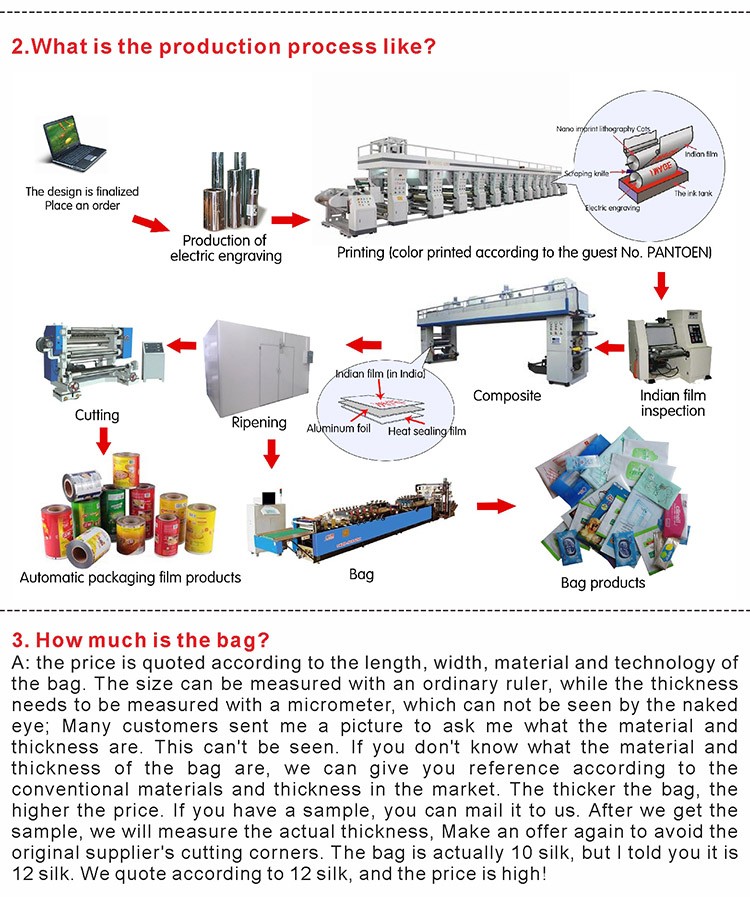

So how is the self-supporting nozzle bag made?

The suction nozzle bag is composed of suction nozzle and self-supporting bag. Each link has high requirements for the process. If it is not mastered well, unqualified products will appear, and problems such as bag expansion, bag breakage and leakage will appear in the process of use. In order to avoid this situation, in the production of self-supporting bags, attention must be paid to the links such as punching, placing the bottom of the bag and heat sealing at the bottom. In particular, the joint part of the fourth layer and the second layer of the self-supporting bag is particularly prone to bag breakage. The horizontal sealing knife is not enough. Heat sealing knives should be added, and heat sealing should be strengthened in some parts. In addition, the self-supporting bag with mouth shall have good opening performance. When making the bag, the static electricity on the surface shall be removed to avoid adsorption between the bag and the bag, which is not conducive to the bag taking by the mouth sealing machine.

At present, there are two methods of self-supporting bag suction nozzle in China: manual suction nozzle and thermal packaging suction nozzle. The temperature is transmitted to the mouth through heat conduction to melt the mouth and weld it with the PE sealing layer of the bag.

Requirements for bag making process of suction nozzle bag

1. Heat sealing temperature

The factors to be considered when setting the heat sealing temperature are: first, the characteristics of the heat sealing material; Second, film thickness; The third is the number of hot sealing and pressing and the size of heat sealing area. Generally, when the number of hot pressing times of the same part is more, the heat sealing temperature can be set lower appropriately.

2. Heat seal pressure

The manufacturer of nozzle bag must apply appropriate pressure during heat sealing to promote the adhesion of heat cover materials. However, if the pressure is too high, the molten material will be extruded, which will not only affect the flatness of the bag, fault analysis and troubleshooting, but also affect the heat sealing effect of the bag and reduce the heat sealing strength.

3. Heat sealing time

Heat sealing time is not only related to heat sealing temperature and pressure, but also related to the performance of heat sealing materials, heating methods and other factors. The specific operation shall be adjusted during actual commissioning according to different equipment and materials.

4. Heating mode

The heating methods of heat sealing knife during bag making heat sealing can be divided into two categories: unilateral heating and bilateral heating. Obviously, the heating mode on both sides is more efficient and practical than that on one side.

There are many problems in the actual production of packaging bags, but there are mainly two prominent problems: one is liquid leakage or air leakage when holding goods; Second, the bag shape is uneven and the bottom seal is asymmetric in the process of bag making. Therefore, how to select materials and adopt better process operation mode plays a decisive role in improving the overall quality of vertical bags.