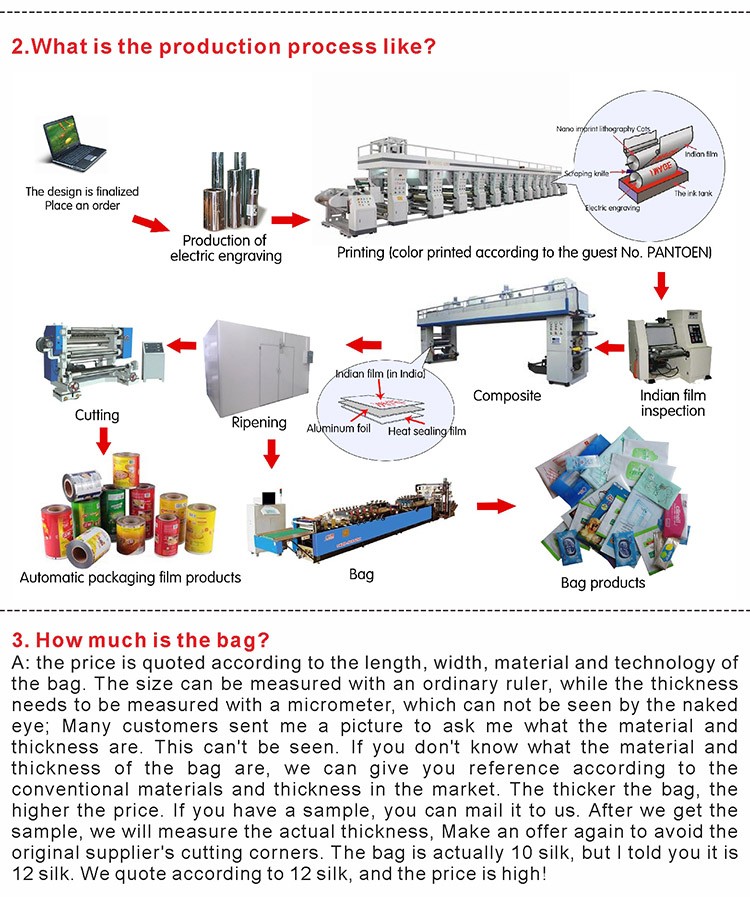

Manufacturer printed customized tomato sauce salad dressing packaging bag color printing logo

- FOB Price:Get Latest Price >

- Min.Order:300 Kg(s)

- Payment Terms:PayPal

- Favorite

Business Type:Manufacturer

Country/Region:China

Ddu Verified

HOT Rank

ZHONGSHAN HEYING PRINTING & PACKAGING CO., LTD

We are professional supplier of Aluminum foil packaging,Composite packaging,Electronic shielding bag,Food packaging bag,Medicine bag,Fruit bag,Automatic packaging roll film,Parafilm.

Business Type:Manufacturer

Country/Region:China

Ddu Verified

HOT Rank

Tomato sauce salad dressing bag

Common materials are as follows:

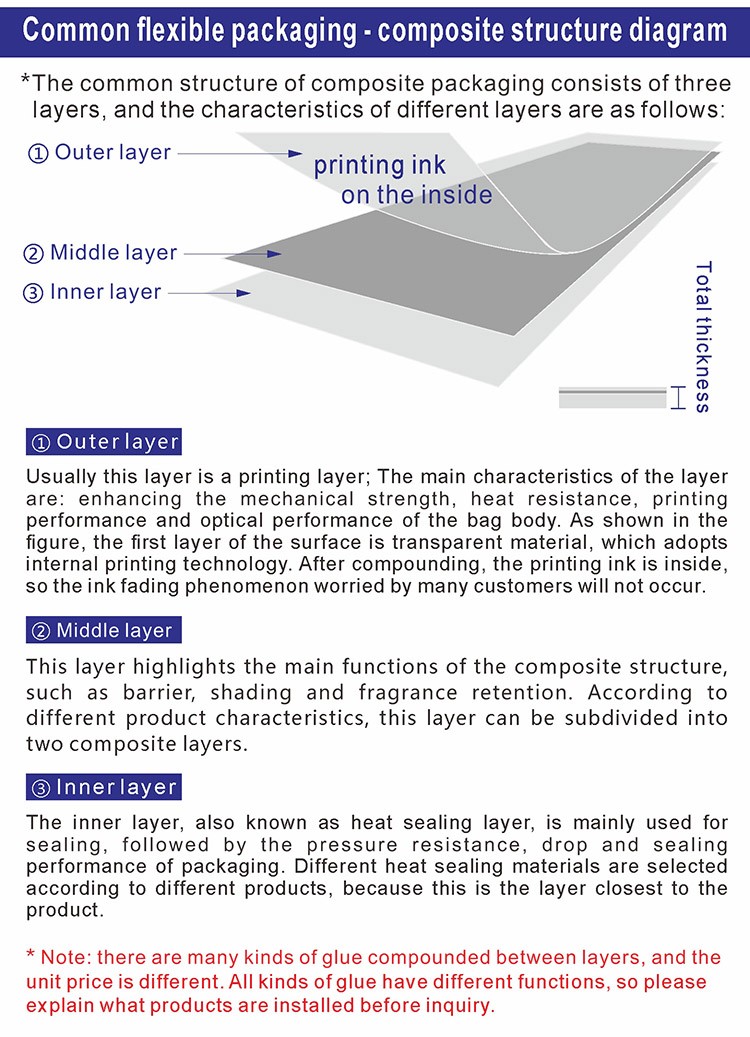

Pet, increase mechanical strength! Crisp! Then according to the demand, combination, various properties, also transparent, in order to increase the barrier performance, use water-resistant PVA high barrier coating! Vacuum bag, also known as close fitting moisture-proof bag, aluminum foil bag and aluminum-plastic composite bag. Vacuum bag, also known as close fitting moisture-proof bag, aluminum foil bag and aluminum-plastic composite bag, is generally made of PET / Al / CPE or PET / NY / Al / CPE. Among them, pet has good printing effect, NY has low oxygen permeability, Al has strong barrier and light tightness, and CPE is the inner layer of packaging. Glue: water soluble glue (more hygienic, environmental protection, no solvent residue) this product has good anti-static, oxygen isolation, shielding, moisture-proof, shading functions and excellent heat sealing. According to the special requirements of users in various industries, the product can add anti-static function, print product description, company trademark and anti-static logo without changing the product performance. High barrier: coextrusing films with high barrier properties of different plastic materials.

There are many kinds of materials for food packaging bags, each with its own advantages and disadvantages. Customers should choose according to their own products. Food packaging is a composite packaging:

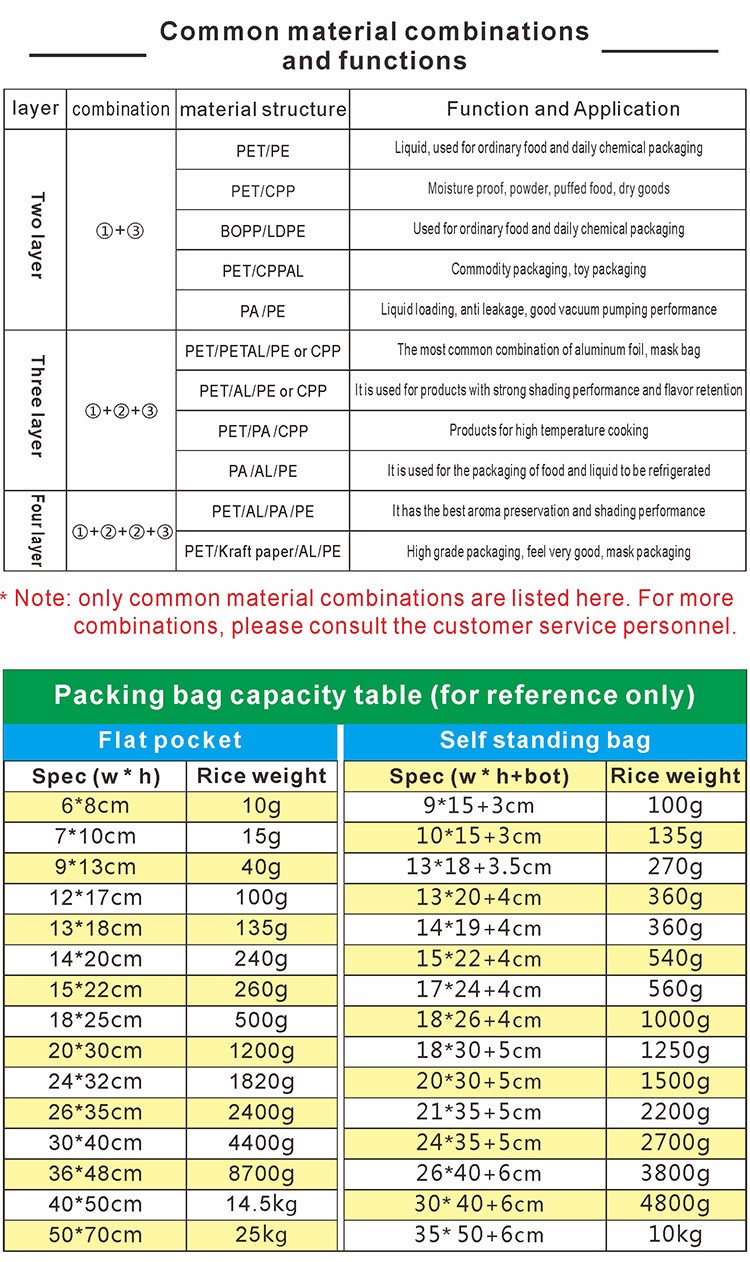

Two layer composite: PA / PE or PA / rcpp; PET / PE or PET / rcpp

Three layer composite: PET / PA / PE; PET/AL/RCPP; PA/AL/RCPP

Four layer composite: PET / PA / Al / rcpp

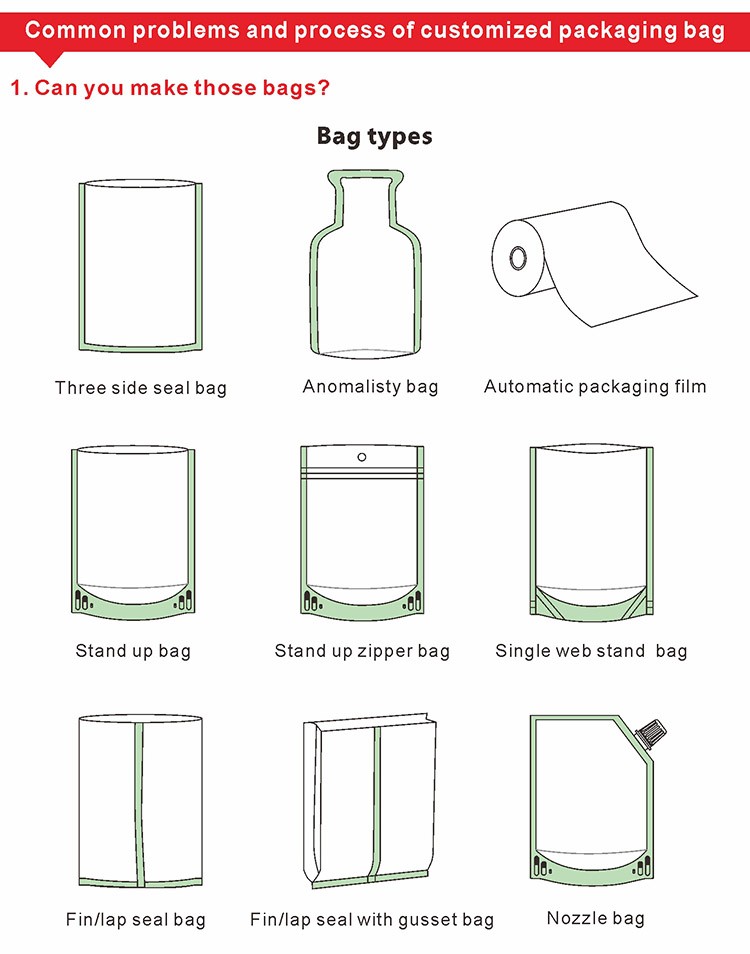

The bag types of vacuum packaging bags can be customized according to customer requirements. The common bag types include three side seal, middle seal organ, side seal, self-supporting bag, etc.